Internet of Things (IoT) | Oil & Gas Industry | Corvalent

| Corvalent

- The Role of IoT in Oil and Gas is Growing Rapidly

- Future Trends and Opportunities

- Challenges and Considerations

- Corvalent's IoT Solutions for the Oil and Gas Industry

- Corvalent’s IoT Solution: World-wide Monitoring is a Gamechanger

- Meeting the Demands of a Fast-Moving Industry

- Our Competitive Advantage

- Next Steps: Partnering for Success

- Addendum

The advent of Industry 4.0 (4IR) has unleashed a level of industrial innovation that, while moving at breakneck speed, is also being embraced in the oil and gas industry with the same enthusiasm, yet with a high level of capabilities, flexibility, and longevity of solutions.

At Corvalent, we know the Internet of Things (IoT) is revolutionizing the oil and gas sector, offering unprecedented opportunities for enhancing operational efficiency, safety, and environmental sustainability. As a cornerstone technology, IoT integrates an interconnected network of devices, sensors, gateways, and software solutions, transforming how industry operations are managed and optimized.

In the complex and critical domain of the oil and gas sector, the introduction of IoT technologies marks a significant stride towards innovation, setting the stage for the emergence of intelligent oilfields and digital pipelines. These technological advances are poised to streamline operations, enhance efficiency, significantly reduce risks, minimize downtime, and refine decision-making processes through the application of real-time data analytics and monitoring.

The transition to IoT-enabled operations signals a transformative phase towards heightened efficiency and sustainability, representing a crucial juncture in the continuous progression of the industry. This executive briefing is intended to provide insights into the challenges and opportunities for IoT solutions in this industry and to introduce Corvalent's suite of IoT and sensor monitoring solutions.

The Role of IoT in Oil and Gas is Growing Rapidly

IoT is reshaping the oil and gas industry by providing real-time data collection, monitoring, analysis, and automation capabilities. With a vast network of connected devices – from drilling rigs, to pipelines, to refineries – IoT enables seamless communication between machines, equipment, and personnel. This translates into enhanced visibility, control, and predictive maintenance, ultimately leading to improved decision-making and cost savings.

Moreover, as we see it, the integration of IoT with advanced analytics, machine learning, and artificial intelligence (AI) technologies empowers oil and gas companies to draw valuable insights from large volumes of operational data. By unlocking this untapped potential, IoT enables effective optimization of critical processes such as production forecasting, supply chain management, and many others.

The oil and gas industry is highly complex, involving diverse processes, systems, and assets spanning exploration, production, transportation, refining, distribution, and sales. As such, IoT can deliver significant value by offering real-time visibility into these interconnected operations, enabling seamless monitoring and management for enhanced performance. Some of the key areas where IoT can drive transformative change include:

Asset Management

By utilizing sensors and connected devices, IoT enables real-time monitoring of equipment and assets, providing valuable insights into performance, maintenance needs, and potential failures. This translates into predictive maintenance strategies that reduce downtime, improve efficiency, and extend the lifespan of critical assets.

Operations Optimization

With an interconnected network of sensors and devices, IoT enables real-time data collection and analysis, empowering operators to make informed decisions for enhancing efficiency, reducing costs, and minimizing risks. By leveraging predictive maintenance and advanced analytics capabilities, companies can optimize processes such as drilling, production, transportation, and storage.

Safety

In hazardous environments like oilfields, ensuring safety is a top priority. With IoT solutions in place, companies can enhance safety by monitoring and tracking equipment, personnel, and environmental conditions in real-time. In case of any anomalies or potential risks, operators can take immediate action to prevent accidents and protect workers.

Environmental Sustainability

The oil and gas industry has long been scrutinized for its impact on the environment. With IoT solutions, companies can monitor emissions, energy consumption, and other environmental factors to identify areas for improvement and implement strategies for reducing their carbon footprint. This not only helps companies comply with regulations but also promotes a more sustainable operation.

Future Trends and Opportunities

The future of IoT in the oil and gas industry looks promising, with advancements such as AI algorithms, edge computing, 5G connectivity, predictive analysis, data storage, and enhanced cybersecurity solutions paving the way for even greater efficiencies and innovations. Notable use cases include Shell's well monitoring solutions, Saudi Aramco's cloud-based predictive analytics, and Chevron's equipment health monitoring, showcasing the diverse applications and benefits of IoT technology.

As the global IoT market in the oil and gas sector is projected to reach $27.7 billion by 2032, the importance of embracing this technology cannot be overstated. By leveraging IoT's capabilities for real-time monitoring, predictive maintenance, and improved operational efficiency, the oil and gas industry can achieve significant advancements in safety, sustainability, and productivity. Overcoming the inherent challenges will require a strategic approach, emphasizing cybersecurity, system integration, cost management, and talent development. Embracing these technological advancements positions companies to thrive in an increasingly competitive and complex industry landscape.

NOTE: To underpin the projected growth and market valuation, the statistic mentioning the IoT market in the oil and gas sector reaching $27.7 billion by 2032 originates from the comprehensive analysis conducted by Market Research Future in their report titled "IoT in Oil and Gas Market Research Report - Global Forecast till 2032." This report provides an in-depth examination of market dynamics, offering valuable insights into trends, challenges, and opportunities shaping the future of IoT in the industry. It is, however, beyond the scope of this briefing.

Challenges and Considerations

While the potential benefits of IoT in the oil and gas industry are significant, there are some challenges that companies must consider when implementing these solutions. Some of the key considerations include:

Data Security

With a vast network of interconnected devices, data security is a top concern for companies. The transmission and storage of sensitive operational data require robust security measures to prevent cyberattacks and protect against potential breaches. Companies must prioritize implementing robust security protocols and regularly update them to stay ahead of potential threats.

Legacy Systems

With many companies in the oil and gas industry using legacy systems, compatibility can be a challenge when integrating IoT solutions. Companies must assess their current infrastructure and plan accordingly for seamless integration with IoT technologies. This may require updating or replacing outdated systems and investing in new technology.

Workforce Training

As with any technological advancement, the adoption of IoT solutions requires proper training for personnel. Companies must invest in employee training to ensure that they have the necessary skills and knowledge to operate and maintain these technologies effectively. This can also help in creating a culture of innovation and continuous learning within the organization.

Data Integration

The sheer volume of data generated by IoT devices can be overwhelming for companies to manage and analyze. It is crucial to have a comprehensive data management strategy in place to effectively integrate and make sense of this data. Companies must also ensure that their analytics capabilities can handle the influx of real-time data and provide actionable insights.

Interoperability

The oil and gas industry is highly complex, with diverse systems and assets from different manufacturers. As such, ensuring interoperability between these systems and IoT devices is crucial for efficient data sharing and analysis.

Communication

Efficient and reliable communication forms the backbone of IoT integration within the oil and gas industry, with 5G, Wi-Fi, and other IoT communication protocols playing pivotal roles. The advent of 5G technology, with its high speed and low latency, revolutionizes the potential for real-time data transmission, supporting critical operations in remote and challenging environments.

Wi-Fi, ubiquitous in its deployment, provides a cost-effective and readily available means for device connectivity, essential for sensor networks and data aggregation points across facilities. Other protocols such as LoRaWAN and Zigbee offer alternatives tailored for IoT applications, enabling long-range communication with minimal power consumption. These technologies are crucial in ensuring that data from sensors and devices are transmitted efficiently, securely, and without delay, supporting the industry's shift towards more automated and remote operations.

Scalability

As companies look to expand their operations, the scalability of IoT solutions becomes a critical consideration. The ability to handle growing volumes of data and integrate with new systems and assets is essential for long-term success.

Corvalent's IoT Solutions for the Oil and Gas Industry

Corvalent offers a comprehensive suite of IoT and sensor monitoring solutions designed specifically for the oil and gas industry. Our cutting-edge technology enables real-time data collection, analysis, and visualization to optimize operations, reduce costs, and improve safety. With our solutions, companies can achieve:

- Predictive Maintenance: Our IoT solutions enable companies to monitor equipment and assets in real-time, identifying potential failures before they occur. This allows for predictive maintenance strategies that minimize downtime, extend asset lifespan, and reduce costs.

- Operational Optimization: By utilizing advanced analytics and machine learning capabilities, our solutions empower operators with valuable insights to optimize critical processes such as production forecasting, supply chain management, and energy efficiency.

- Real-time Monitoring and Tracking: Our solutions offer real-time visibility into assets, personnel, and environmental conditions, enhancing safety and enabling quick response to any anomalies or potential risks.

- Compliance with Regulations: Corvalent's IoT solutions can help companies comply with regulations related to emissions, energy consumption, and other environmental factors. By monitoring and tracking these metrics, companies can identify areas for improvement and implement strategies for reducing their carbon footprint.

- Scalability: Our solutions are designed to be highly scalable, allowing companies to expand their operations without worrying about the limitations of their IoT systems.

- Enhanced Data Security: At Corvalent, we prioritize data security and offer robust measures to protect sensitive operational data from potential cyber threats. This ensures that our clients can trust our solutions to keep their data safe.

- Ease of Integration: Our IoT solutions are designed to seamlessly integrate with existing systems and assets, making it easier for companies to adopt these technologies without major disruptions to their operations.

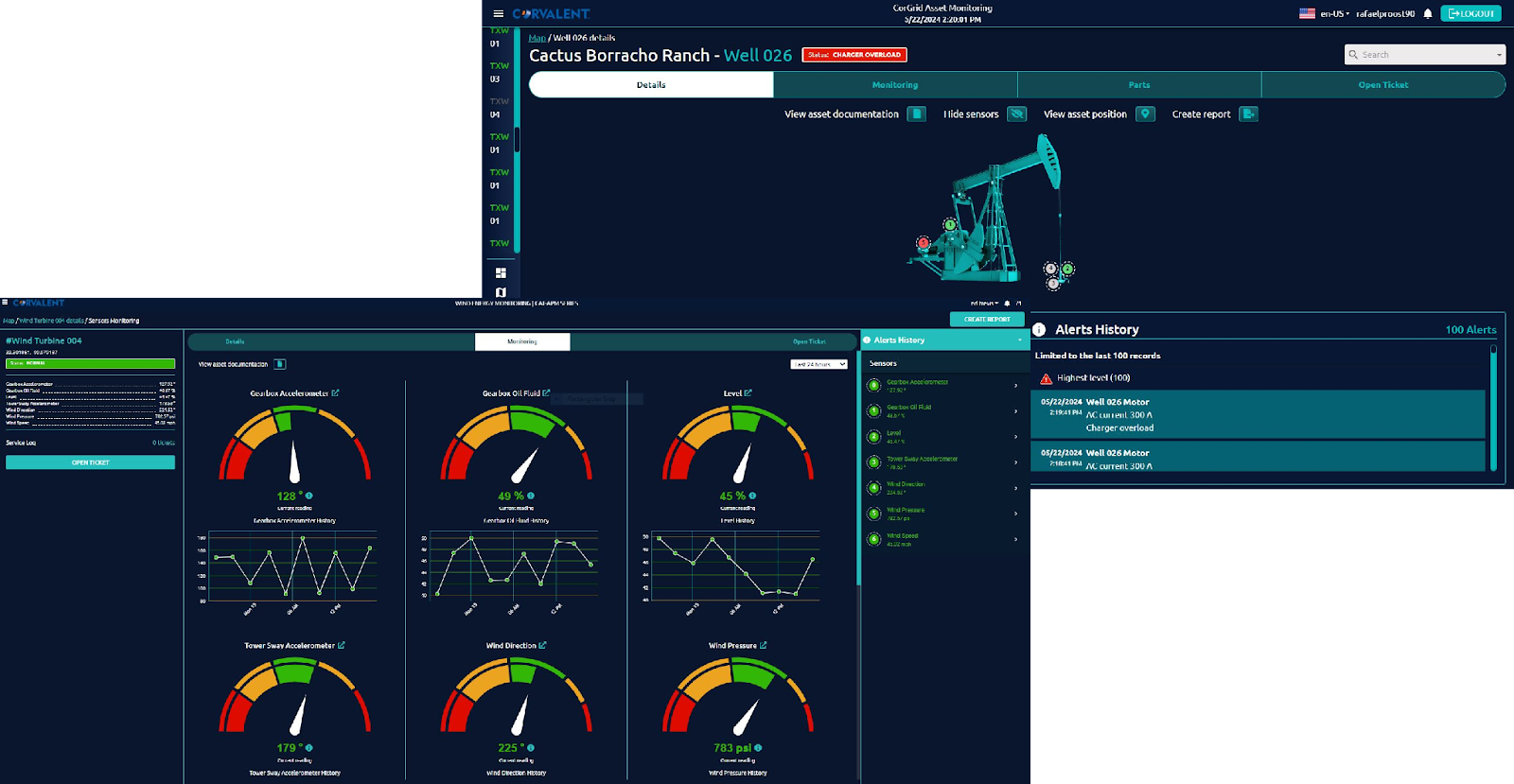

Corvalent’s IoT Solution: World-wide Monitoring is a Gamechanger

Imagine monitoring all IoT devices, sensors, and alarms from a single pane of glass, anywhere in the world.

The oil and gas industry is rapidly adopting IoT technologies to drive operational efficiency, improve safety, and promote environmental sustainability. By leveraging real-time data collection, advanced analytics, and predictive maintenance capabilities, companies can optimize processes, reduce costs, and protect their assets. As a leading provider of IoT solutions for the oil and gas industry, Corvalent is committed to helping our clients stay ahead of the curve with cutting-edge technology and unparalleled service.

We understand the challenges faced by oil and gas companies in implementing IoT solutions, and have designed our suite of products to address these specific needs. Our industrial-grade sensors, IoT appliances, and cloud-based platform provide a highly scalable, secure, and interoperable solution for real-time data collection, monitoring, analysis, and automation.

Our robust security measures ensure the confidentiality and integrity of your operational data while our edge computing capabilities enable local data processing for reduced latency and improved reliability. Our platform also offers the flexibility to integrate with existing systems, enabling seamless communication between different assets and processes.

Corvalent stands at the forefront of industrial computing and IoT innovation, offering robust solutions specifically designed for the oil and gas industry. Our CorGrid IoT Platform, combined with sensor technology and edge computing capabilities through IoT Edge & Gateway Systems, provides a seamless, integrated approach to tackling the industry's most pressing challenges.

Introducing Corvalent's IoT Solutions for Oil and Gas

Corvalent is a leading provider of industrial computing solutions, specializing in ruggedized systems designed for harsh environments such as those found in the oil and gas industry. With over 30 years of experience, we understand the unique challenges and requirements of this industry and offer a suite of IoT and sensor monitoring solutions to help companies achieve their operational goals. Some of our key offerings include:

- Industrial IoT Gateways: Our industrial-grade gateways are designed for reliable data collection, processing, and transmission in remote locations. These ruggedized devices are capable of handling harsh environmental conditions and can seamlessly integrate with existing systems and sensors.

- Edge Computing Solutions: Our edge computing solutions enable real-time data processing and analysis at the source, reducing latency and enhancing decision-making capabilities. This also reduces the amount of data that needs to be transmitted, saving on bandwidth costs.

- Remote Asset Monitoring: With our sensor-based remote asset monitoring solution, companies can track equipment performance, receive alerts for potential failures or anomalies, and remotely control critical assets for enhanced efficiency and reduced downtime.

- Predictive Maintenance: Our predictive maintenance solution utilizes machine learning algorithms to analyze operational data and identify potential equipment failures before they occur. This enables companies to proactively plan maintenance activities, reducing costs and minimizing downtime.

Meeting the Demands of a Fast-Moving Industry

The integration of IoT solutions within the oil and gas industry heralds a paradigm shift, ushering in unprecedented efficiency, safety, and decision-making capabilities. On the benefit side, IoT enables real-time monitoring and control over vast and complex operations. This granular visibility allows for the immediate identification and resolution of issues, significantly reducing the risk of costly downtime and enhancing operational safety.

Additionally, the predictive analytics afforded by IoT can foresee equipment failures before they happen, ensuring that maintenance can be conducted proactively, rather than reactively. This not only prolongs the lifespan of the equipment but also optimizes the performance and safety of operations.

On the flip side, while IoT presents a host of opportunities, it also introduces certain challenges that need to be navigated. The sheer volume of data generated can be overwhelming, necessitating sophisticated data processing and analysis capabilities to extract actionable insights. Privacy and security concerns are paramount, given the sensitive nature of the data being collected and transmitted. The potential for cyberattacks necessitates robust security protocols to protect against data breaches and ensure the integrity of operational systems. Additionally, the integration of IoT technology with existing infrastructure may present compatibility issues that require innovative solutions to overcome.

Despite these challenges, the opportunities presented by IoT in enhancing operational efficiency, safety, and profitability are immense. By carefully addressing the potential hurdles and leveraging the full suite of capabilities offered by IoT, the oil and gas industry can achieve significant advancements, setting a new standard for excellence in operations.

Real-Time Monitoring and Predictive Maintenance

Our IoT sensors and CorServers facilitate continuous monitoring of critical equipment and environmental conditions across widespread and remote locations. This enables predictive maintenance, reducing downtime by identifying potential issues before they escalate, and ensuring operational continuity.

Enhanced Safety and Compliance

Leveraging IoT technology, Corvalent enhances safety protocols by enabling real-time hazard detection and response mechanisms. This not only protects personnel but also ensures compliance with rigorous industry standards and environmental regulations.

Operational Efficiency and Cost Savings

By harnessing the power of real-time data analytics, our solutions optimize production processes, streamline logistics, and reduce energy consumption. The result is significant cost savings, improved asset utilization, and enhanced overall operational efficiency.

Scalability and Flexibility

Understanding the dynamic nature of the oil and gas industry, Corvalent designs solutions that are both scalable and flexible. Our platforms adapt to evolving operational needs and technological advancements, ensuring long-term viability and return on investment.

Our Competitive Advantage

What sets Corvalent apart is our dedication to long-life industrial hardware, off-the-shelf or built-to-spec, ensuring reliability and supportability over the long term. Unlike competitors, our U.S.-based manufacturing and design capabilities allow for unparalleled customization and quick adaptation to client-specific requirements. Additionally, our emphasis on security solutions addresses the industry's growing concerns over cybersecurity threats, providing peace of mind and safeguarding critical infrastructure.

- Comprehensive Integration: Corvalent's end-to-end IoT solutions seamlessly integrate with existing infrastructure in the oil and gas industry, facilitating the effortless collection, processing, and analysis of data. This integration ensures that companies can rapidly adapt to technological advancements and operational changes without the need to overhaul their current systems.

- Customizable and Future-Proof: The modular nature of Corvalent's offerings allows for tailor-made solutions that meet the exact needs of each client. This customizability, combined with a focus on long-life hardware and scalable platforms, ensures that the investments made today remain relevant and effective as the industry evolves.

- Enhanced Operational Visibility and Decision-Making: By providing real-time monitoring and predictive analytics, Corvalent's solutions offer unprecedented visibility into every aspect of operations. This visibility enhances decision-making, allowing for proactive measures that minimize downtime, reduce costs, and optimize performance across the board.

Next Steps: Partnering for Success

In an industry where efficiency, safety, and reliability are non-negotiable, Corvalent stands as a trusted partner, bringing 30 years of experience in industrial automation and control. Our IoT solutions are not just about technology; they're about driving profits, performance, and sustainable growth for the oil and gas industry. By choosing Corvalent, you're investing in a future where operational challenges are transformed into opportunities for innovation and excellence.

To explore how Corvalent can revolutionize your operations and contribute to your success story, contact us today. Together, let's harness the power of IoT to navigate the complexities of the oil and gas industry and unlock new horizons of productivity and profitability.

Addendum

Crucial Questions

- What specific objectives do we aim to achieve with the deployment of IoT and wireless sensor technology for remote monitoring?

- How will IoT and sensor technology integrate with our existing operational infrastructure?

- What are the initial and ongoing costs associated with deploying this technology?

- Which operational parameters are most crucial to monitor in real-time and why?

- What is the expected ROI, and how will we measure the success of implementing IoT solutions?

- How will data security and privacy be ensured in the deployment of this technology?

- How scalable is the IoT solution, and can it adapt to future operational expansions or changes easily?

- What types of sensors and IoT devices are most suitable for our specific operational needs?

- How will the data collected via these sensors be processed, analyzed, and utilized for decision-making?

- What are the redundancy and failover mechanisms to ensure continuous monitoring and data collection?

- How user-friendly is the system, and what level of training will our team need?

- Can the system provide predictive maintenance capabilities, and if so, how accurate are these predictions?

- How does the remote monitoring system communicate alerts, and can it integrate with our existing emergency response protocols?

- What is the durability and reliability of the sensors and devices in harsh operational environments?

- Is there any proven case study or reference from a similar industry that has benefited from such technology?

- How long is the implementation phase, and what disruptions, if any, should we anticipate during this period?

- What ongoing support, maintenance, and updates does the technology provider offer post-implementation?

- How does the IoT solution ensure compliance with international environmental and safety standards specific to the oil and gas industry?

- Can the IoT platform be customized to support multi-language interfaces for global operations?

- What is the process for upgrading the system as new sensor technologies and data analytics capabilities become available?

- How does the system facilitate cross-departmental collaboration and information sharing to improve overall operational efficiency?

- In what ways does the technology provider assist in the integration of IoT data with other business intelligence tools and platforms?

- What measures are in place to ensure the longevity and sustainability of the IoT devices under extreme operational conditions?

- How can the IoT solution assist in achieving corporate sustainability and carbon reduction goals?

- How is user access to the IoT system managed and controlled to prevent unauthorized access or data breaches?

Recommended Implementation Strategies and Timelines

Successfully deploying IoT solutions in the oil and gas industry requires a well-structured implementation strategy that minimizes disruption and maximizes efficiency. At Corvalent, we advocate for a phased approach, starting with a pilot program that allows us to test the technology on a small scale before a full-scale rollout.

Phase 1: Pilot Program (1-3 Months)

-

Select a limited yet representative section of operations as the test bed for the pilot.

-

Focus on integrating sensors and IoT devices with critical systems to evaluate performance, compatibility, and any potential issues.

-

Use this phase to fine-tune the system, ensuring smooth integration with existing infrastructure.

Phase 2: Full-Scale Deployment (3-6 Months)

-

Based on the insights and outcomes of the pilot program, proceed with the full-scale implementation of the IoT solution across all operations.

-

This phase involves expanding the installation of sensors and IoT devices, enhancing data analytics capabilities, and ensuring all personnel are trained and comfortable with the new technology.

Optimization and Continuous Improvement (Ongoing)

-

Post-deployment, focus shifts to optimizing the system based on real-world operation data, refining predictive analytics, and ensuring the technology adapts to evolving operational needs.

-

Implement a feedback loop with operations and maintenance teams to continuously improve system performance and user experience.

The total time from the pilot program to full-scale deployment is estimated to range from 4 to 9 months, depending on the scale of operations and specific challenges encountered. Corvalent is committed to providing ongoing support, maintenance, and updates post-implementation to ensure the IoT solutions deliver sustainable value and adapt to future needs.

About the Author